Halamanee Aerospace Pvt. Ltd. (Unit I & II)

Halamanee Aerospace Group of Companies– Your One-Stop Partner for Precision Aerospace & Defence Manufacturing

We would like to introduce Halamanee Aerospace Group of Companies, your one-stop solution provider for high-precision Aerospace, Space, and Defense manufacturing.

Our journey began with Halamanee Precisions, a tool-room-based facility specializing in Wire EDM, Sparking, and Precision Cutting.

Expanding into Aerospace & Defense as Halamanee Aerospace Pvt Ltd, we now operate two advanced Aerospace and Defence precision components manufacturing units built to the highest International Industry standards.

Our One-Stop Solutions:

- Complete In-House Manufacturing Solutions – From precision machining,sub-assemblies to sheet metal manufacturing.

- AS9100D & Industrial Certifications: “We are an AS9100D-certified company, ensuring the highest aerospace quality standards. Additionally, We hold ISMS, EHS & OHS certifications, reinforcing our commitment to safety, security, and operational excellence.”

- One-stop solution provider: “We offer a fully integrated approach, eliminating multi-vendor complexities. Our services range from Precision tool-room setup to Structural Components and Sheet metal manufacturing entities.”

- “We cater to prestigious global aerospace and defence customers, ensuring superior quality and precision.”

- Advanced infrastructure: “Our facility houses advanced machines, including branded DOOSAN,HAAS,PVM, 3/4-axis, and 5-axis simultaneous machines.

- Aerospace-Grade Manufacturing Excellence – Structural components, sub-assemblies at the International Standards.

- Leading Supplier to the Global and National Aerospace and Defence Industries.

- Advanced Sheet Metal Manufacturing Facility – “Airbus Approved Supplier“, a sheet metal manufacturing unit enables high-precision bending and forming.”

- Advanced Tool Room Facility – Wire EDM, Sparking, Wire Cutting Machines.

- Future Expansion – NADCAP-certified Special Process Treatment Plant (4-acre setup) for in-house finishing & reduced lead times.

- Dedicated Cloud Systems,ERP and FTP servers : Ensuring Traceability and Security of Aerospace and Defence documents.

Built for Precision. Backed by Purpose.

At the heart of our journey lies Halamanee Aerospace Pvt. Ltd., our flagship unit and the foundation of our manufacturing excellence.

This is where big ideas become high-precision realities.

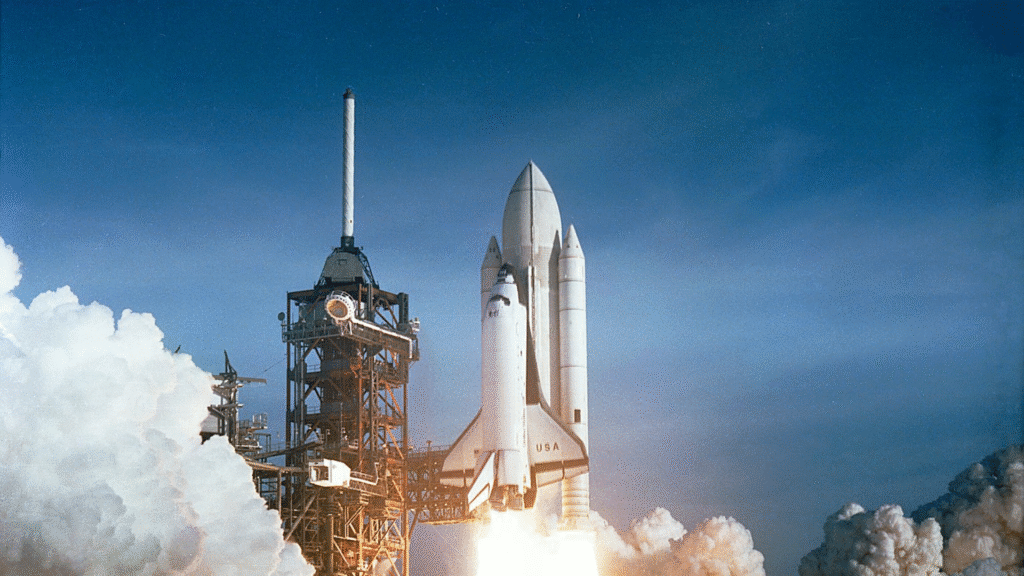

Equipped with a full-fledged aerospace manufacturing setup, Units I & II specialize in the production of mission-critical components for Aerospace, Defence, Space, Medical, and Oil & Gas sectors. From a complex machined housing to the closest tolerance-based part, every component that leaves this unit is built with exactitude, speed, and global compliance.

Here’s what sets us apart:

- Global Certifications – AS9100D, ISO 9001, ISO 45001, ISO 27001, and ISO 14001

- Advanced CNC Machines – Multi-axis machining, VMCs, HMCs, turning centers

- Dedicated QA Lab – Fully equipped for inspection, traceability, and 3D CMM validations

- Trusted by Industry Giants – HAL (all 8 divisions), DRDO, ISRO, and more

- On-Time, Every Time – Agile processes, in-house tooling, and zero-compromise workflows

Whether it’s powering a fighter jet or contributing to space missions, this unit delivers more than just precision — it delivers trust.

But what truly defines Halamanee Aerospace Pvt. Ltd. is not just the machines — it’s the mindset.

Every technician, engineer, and quality expert in our unit works with a singular purpose: to deliver beyond expectations. It’s a culture shaped by continuous learning, cleanroom discipline, and a deep-rooted passion for aerospace excellence.

What Happens Inside the Unit?

- Design to Dispatch Under One Roof – From 3D modeling and CAM programming to final inspection, everything happens in-house. This gives us full control, faster turnaround, and unmatched quality ownership.

- Prototyping to Production – Whether it’s a one-off prototype or a long-term supply contract, we’re built for both scale and speed.

- Complex Geometry Experts – Thin walls, tight tolerances, exotic alloys — we thrive on the kind of challenges that others avoid.

- Strong Process Backbone – SOPs, real-time tracking, traceable batches, and error-proof operations ensure every component is audit-ready and production-stable.

Why Clients Choose This Unit?

Because we speak the language of OEMs — quality benchmarks, documentation, and delivery standards that meet global aerospace expectations.

Unit I & II are more than just manufacturing floors. They are the nerve center of Halamanee’s reputation, where innovation meets execution every single day.